A Guide to Solar Mounting Options for Different Roof Types

December 10, 2025

In the solar industry, we often say that the panel grabs the headlines, but the mounting system does the heavy lifting. As an engineer at Antaisolar, I have reviewed thousands of project designs, and if there is one golden rule in roof solar mounting, it is this: one size never fits all.

A mounting system is not just a piece of metal connecting a module to a building; it is the structural bridge between energy generation and architectural integrity. Whether you are dealing with a century-old clay tile roof or a modern TPO membrane on a commercial warehouse, the physics change. The thermal expansion coefficients change. The waterproofing requirements change.

This guide explores the engineering nuances behind different roof types for solar and how to select the right solar panel mounting options to ensure safety, efficiency, and longevity.

This guide explores the engineering nuances behind different roof types for solar and how to select the right solar panel mounting options to ensure safety, efficiency, and longevity.

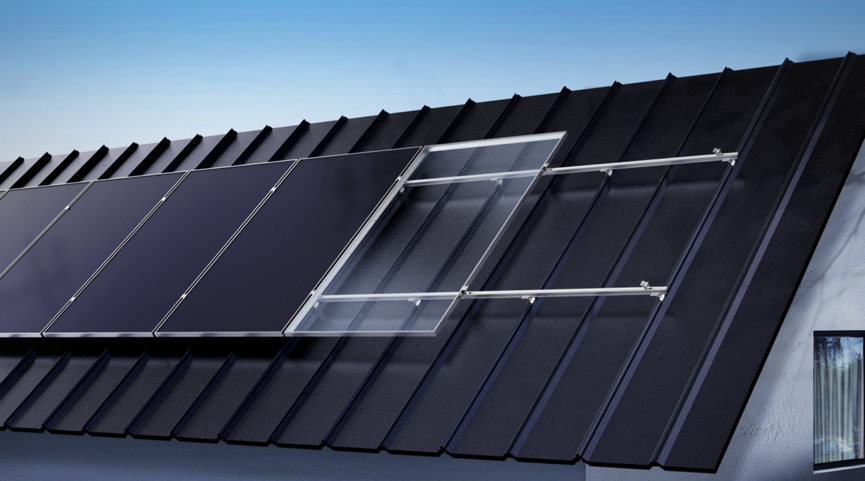

Metal Roofs: Precision and Compatibility in C&I Projects

Metal roofs dominate the Commercial and Industrial (C&I) sector. While they appear sturdy, they present unique challenges regarding profile matching and thermal movement.

The Challenge of Profile Variety

Metal roofs come in countless shapes—Trapezoidal, Corrugated, Kliplok, and Standing Seam. A generic solution here is dangerous; a mismatch can lead to loose connections or, worse, roof damage.

The Solution: Non-Penetrative Clamps

For profiles like Kliplok (Angle Chi) and Standing Seam, the priority is maintaining the roof's warranty. We utilize clamp-based solutions that grip the seam or rib without piercing the metal sheet. This non-penetrative approach preserves the roof's waterproofing integrity.

Mounting Configurations

-

Base & Rail System: The traditional robust choice for high-wind zones.

- Mini Rail System: A cost-effective alternative that reduces material usage by utilizing short rail sections, ideal for trapezoidal roofs.

Material Note: At Antaisolar, we use AL6006-T6 aluminum alloy for these components. Its superior corrosion resistance is non-negotiable for metal roofs, which often face harsh industrial environments. For clients seeking higher yields, we also deploy Triangle Systems or Adjustable Tilt Systems on flat metal roofs to optimize the angle of incidence for sunlight.

Tile Roofs: Mastering the Art of Delicate Installation

In residential markets, tile roofs (Ceramic, Spanish, Slate, or Concrete) are the standard. However, tiles are brittle. The primary engineering concern here is installing a heavy solar array without cracking the waterproofing layer beneath.

The "Hook" Strategy

Direct drilling through a tile is rarely the right answer. Instead, we rely on a sophisticated Hook System. These stainless steel or aluminum hooks slide under the tile, anchoring directly to the roof rafter.

Versatility and Waterproofing

Because tiles vary wildly—from flat slate to curved Spanish waves—the hooks must be adaptable.

- Universal Compatibility: Our hooks are designed to accommodate different curvatures and batten heights.

- Waterproof Integrity: The design focuses on ensuring the tile sits flush after installation. We emphasize double-flashing details and careful handling to ensure the roof’s original waterproof performance remains 100% intact.

- Pre-assembly: To reduce the time installers spend walking on fragile tiles, our hook systems come highly pre-assembled, minimizing the risk of accidental breakage during installation.

Concrete Roofs: Stability on Flat Surfaces

Flat concrete roofs are staples of schools, factories, and commercial complexes. The advantage of a flat roof is accessibility; the disadvantage is the lack of a natural tilt for the solar panels.

The Ballast System (Non-Penetrative)

Drilling into a flat concrete roof requires expensive resealing to prevent pooling water from leaking through. The superior engineering solution is the Ballast System. By using lightweight concrete blocks as counterweights, we secure the array using gravity and aerodynamic design rather than mechanical penetration. This preserves the roof deck completely.

Maximizing Efficiency via Tilt

Since the roof is flat, the mounting system must create the angle. We utilize Adjustable Tilt Systems that allow installers to set the precise angle required to capture maximum solar irradiance based on the site's latitude.

Flexibility

These systems are designed for flexibility. Whether the roof has obstacles like HVAC units or vents, the pre-assembled, modular nature of the ballast system allows for rapid layout adjustments on-site.

TPO Roofs: The Specialist for Soft Membranes

Thermoplastic Polyolefin (TPO) roofs are becoming increasingly popular in commercial buildings due to their reflective properties. However, TPO is a soft membrane; it cannot handle sharp edges or heavy point loads.

100% Waterproofing Focus

The cardinal sin on a TPO roof is a leak. Standard metal mounts can abrade the soft surface over time due to thermal expansion rubbing.

The Antaisolar Approach

Our TPO solution is engineered for chemical and physical compatibility.

- Support Seals: We utilize specific support seals that bond or sit harmlessly against the TPO membrane, ensuring a non-penetrative fix.

- Membrane Protection: The system is designed to distribute weight evenly, preventing the mount from sinking into or tearing the membrane under snow or wind loads.

- Durability: Like our metal solutions, we employ high-corrosion-resistant AL6006-T6 alloy to match the long lifespan of modern TPO materials.

The Antaisolar Advantage: Why Engineering Matters

Understanding roof types for solar is step one. Step two is choosing a partner who innovates on those basics. At Antaisolar, we don't just bend metal; we engineer stability. Here are four ways we elevate roof solar mounting:1. Antai 6A22: Strength Redefined

Standard industry aluminum (6005-T6) is good, but we wanted better. We developed our proprietary Antai 6A22 alloy. Through heat treatment and composition optimization, we achieved a strength increase of 32.6% over standard alloys. This means your system can withstand stronger typhoons and heavier snow loads without adding weight.2. SnapFit: Speed is Money

Labor costs can kill a project's ROI. We patented the SnapFit joint technology, allowing for single-handed installation. By snapping components together rather than fiddling with screws and nuts at dangerous heights, we have seen installation efficiency improve by up to 50%.3. SolarAid: Digital Planning

We support our hardware with software. Our SolarAid platform allows engineers to input project parameters and generate detailed design drawings and Bills of Materials (BOM) in just a few steps. It eliminates the guesswork before the team even arrives at the site.4. Global Trust

We back our engineering with data. With 41.7GW of global shipments and a 15-year warranty, our systems are time-tested. We don't just sell a product; we sell the assurance that the roof will remain secure for decades.Conclusion

When you look at the landscape of solar panel mounting options, it becomes clear that the "roof" is not a single category—it is a variable environment.A metal roof demands thermal flexibility. A tile roof demands a delicate touch. A concrete roof demands aerodynamic ballast. A TPO roof demands chemical compatibility.

At Antaisolar, we believe that choosing the correct mounting solution is the most critical decision in ensuring the long-term structural safety and waterproof reliability of a PV station. It is the foundation of your investment.

Ready to secure your solar investment? Don't guess on your mounting specs. Contact Antaisolar’s engineering team today for a customized design proposal that maximizes your roof's potential and your project's ROI.

end