On the Roof, Minutes Matter: A Practical Look at SnapFit PV Mounting for C&I Projects

December 10, 2025

If you have ever spent a summer afternoon on the roof of a logistics center or a factory, you know that the environment is unforgiving. The heat radiates upward from the membrane or metal surface, wind gusts challenge your balance, and the clock is always ticking.

In my years working with EPC contractors and installers across the globe, I have learned that the success of a commercial solar installation isn't determined in the boardroom; it is determined by the workflow on that roof.

For a long time, the industry focused purely on the cost of materials—the price per watt of the module or the price per kilogram of the steel. But as module prices stabilize and become transparent, the economic battleground has shifted. Today, we are facing a reality where labor cost is the fastest-growing segment of total project expenditure.

This article takes a pragmatic look at this industry shift and explains why we at Antaisolar developed the SnapFit system not just as a product, but as a solution to the "time-trap" of modern solar construction.

The Market Reality: The Cost of Complexity

Let’s be honest about the current state of rooftop solar installation. The demand for C&I (Commercial and Industrial) projects is skyrocketing as businesses seek energy independence. However, the installation teams on the ground are under immense pressure.

Schedules are tighter than ever. A project that used to allow for three weeks is now expected to be finished in two. Furthermore, finding skilled labor is becoming increasingly difficult. When you combine high turnover rates with complex installation systems, you get a recipe for inefficiency.

I have visited sites where highly paid technicians spend 30% of their day just sorting through bags of loose screws, switching drill bits, or realigning rails that shifted during the process. In an industry where efficiency is profitability, these micro-delays add up. A wasted minute on one module, multiplied by a 5-megawatt roof project, equals hundreds of hours of lost labor capital.

The Core Problem: Why "Old School" Doesn't Work Anymore

The traditional approach to a rooftop solar mounting system was often borrowed from heavy construction: lots of steel, lots of bolts, and complex assembly.

The core problem with this approach in today’s economy is the "multi-step penalty." Traditional clamps often require a worker to:

1.Position the clamp.

2.Hold the nut underneath.

3.Align the bolt.

4.Torque it down.

5.Repeat thousands of times.

This process requires dexterity and focus. As fatigue sets in during the afternoon, dropped screws and misaligned clamps become common. This is the "hidden cost" that doesn't appear on a Bill of Materials (BOM), but it bleeds the project's profit margin. To protect margins without sacrificing build quality, the industry needs to shorten the construction cycle to offset rising labor rates.

The Industry Shift: From Material Intensity to Design Efficiency

We are witnessing a fundamental transformation in solar engineering. The industry is moving away from "how heavy can we make it?" to "how fast can we install it?"

Modern commercial solar installation is evolving toward standardized workflows. The goal is to reduce the cognitive load on the installer. The best mounting systems today are those that require the least amount of thinking and the fewest amount of physical movements. We call this philosophy "Less is More."

At Antaisolar, we realized that to achieve a truly fast solar installation, we had to engineer the complexity out of the field and into the factory. This was the genesis of the SnapFit system.

Antaisolar’s SnapFit: A Practical Solution to "Time-Traps"

When we designed SnapFit, we didn't just look at the metal; we looked at the human hand. We asked: "How can we make the connection process intuitive?"

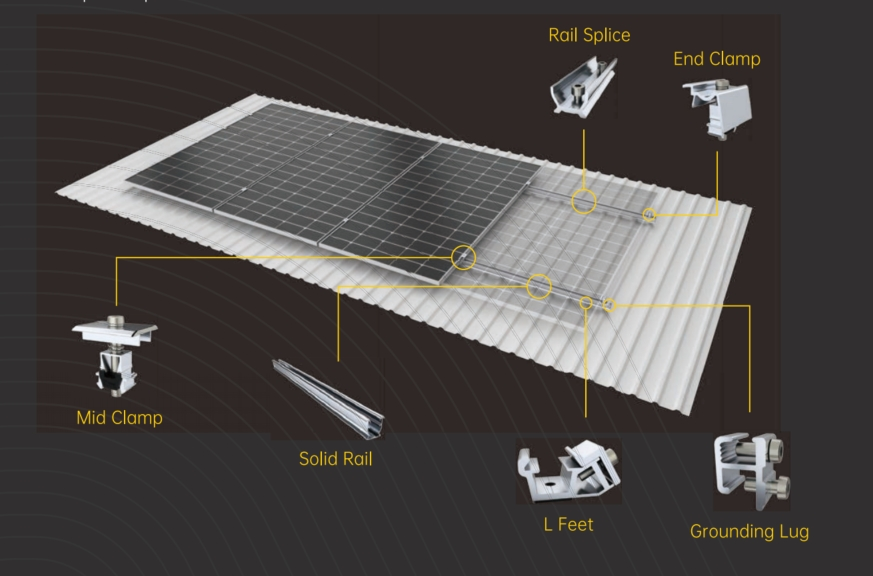

The SnapFit system is our answer to the demand for speed. It utilizes an "Elastic Drive" design mechanism that transforms the installation experience. Instead of the traditional fumble with screws and nuts, SnapFit relies on a standardized, four-step logic: Place, Rotate, Press, Clip.

1. The "Flash" Installation Experience

The feedback we get from installation crews is that it feels like a "flash" assembly. You place the component, rotate it into position, press it down, and it clips securely. There is no need for complex alignment. The tactile "click" gives the installer immediate confirmation that the bond is secure, removing the guesswork.

2. The Power of One Tool

Nothing kills momentum like having to switch tools. We engineered the entire SnapFit system to be compatible with a single M8 tool kit. Whether you are adjusting the base or tightening the final clamp, the tool in your hand never needs to change. This seemingly small detail eliminates the friction of tool management on the roof.

3. Pre-Assembly is Key

We shifted the labor from your expensive job site to our controlled factory environment. SnapFit components arrive highly pre-assembled. This reduces the scattering of parts on the roof and lowers the skill threshold required for installation.

4. Material Science: 6A22 High-Performance Alloy

Speed means nothing if the system isn't robust. This is where our materials engineering comes into play. We utilize 6A22 high-performance aluminum alloy.

Standard industry supports often use 6005-T6 aluminum. However, our 6A22 alloy boasts a tensile strength of approximately 300 MPa and a yield strength of 285 MPa. This is significantly stronger than industry norms. It allows us to optimize the profile for weight and handling speed without compromising structural integrity or wind/snow load resistance. It is strong, yet light enough to handle quickly.

Real-World Value: ROI Beyond the Hardware

When pitching to investors or project owners, the conversation must move beyond the price per watt of the rack. We need to talk about the Total Cost of Ownership (TCO) and ROI.

Efficiency Boost

Internal data and field trials have shown that the SnapFit system can increase installation efficiency by up to 50% compared to traditional mounting solutions. If you can finish a project in half the time, you are effectively halving your labor expenditure per watt. That is direct profit recovery.

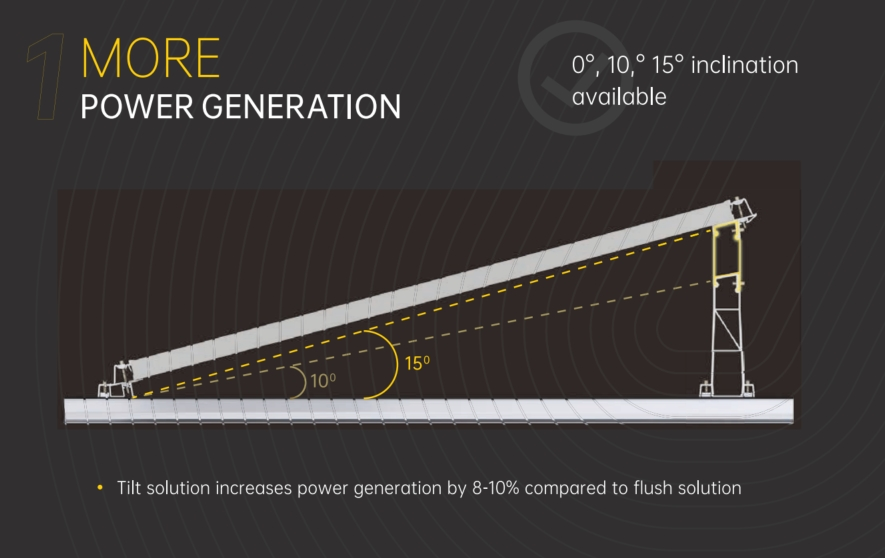

Energy Generation Gains

The SnapFit mounting system isn't just about holding panels; it's about positioning them for maximum yield. The system offers flexible tilt angles—0°, 10°, and 15°. Compared to a completely flat layout, utilizing these tilt options can increase power generation by 8% to 10% depending on the latitude.

Capacity Optimization

Space is money in C&I projects. SnapFit supports an East-West (dual orientation) installation option. By installing panels in an East-West configuration, you minimize the shading gap required between rows. This allows you to fit more modules on the same roof surface, increasing the total installed capacity by 10% to 15%. For the building owner, this means higher long-term energy yields from the same real estate asset.

Conclusion

In the high-stakes environment of a rooftop, every minute carries a cost. The old ways of "nut-and-bolt" assembly are simply not sustainable in a market where labor is premium and timelines are compressed.

SnapFit represents more than just a bracket; it is a management tool. It allows EPCs to predict their schedules with greater accuracy, reduce physical strain on their workforce, and deliver projects faster.

At Antaisolar, our vision is to "Raise a Green World." We believe that to achieve this, we must make the transition to renewable energy as frictionless as possible. By providing a rooftop solar mounting system that respects the installer's time and the investor's wallet, we are paving the way for a more efficient, profitable, and sustainable solar future.

When you are up on that roof, minutes matter. Make sure your mounting system works as hard as you do.

end